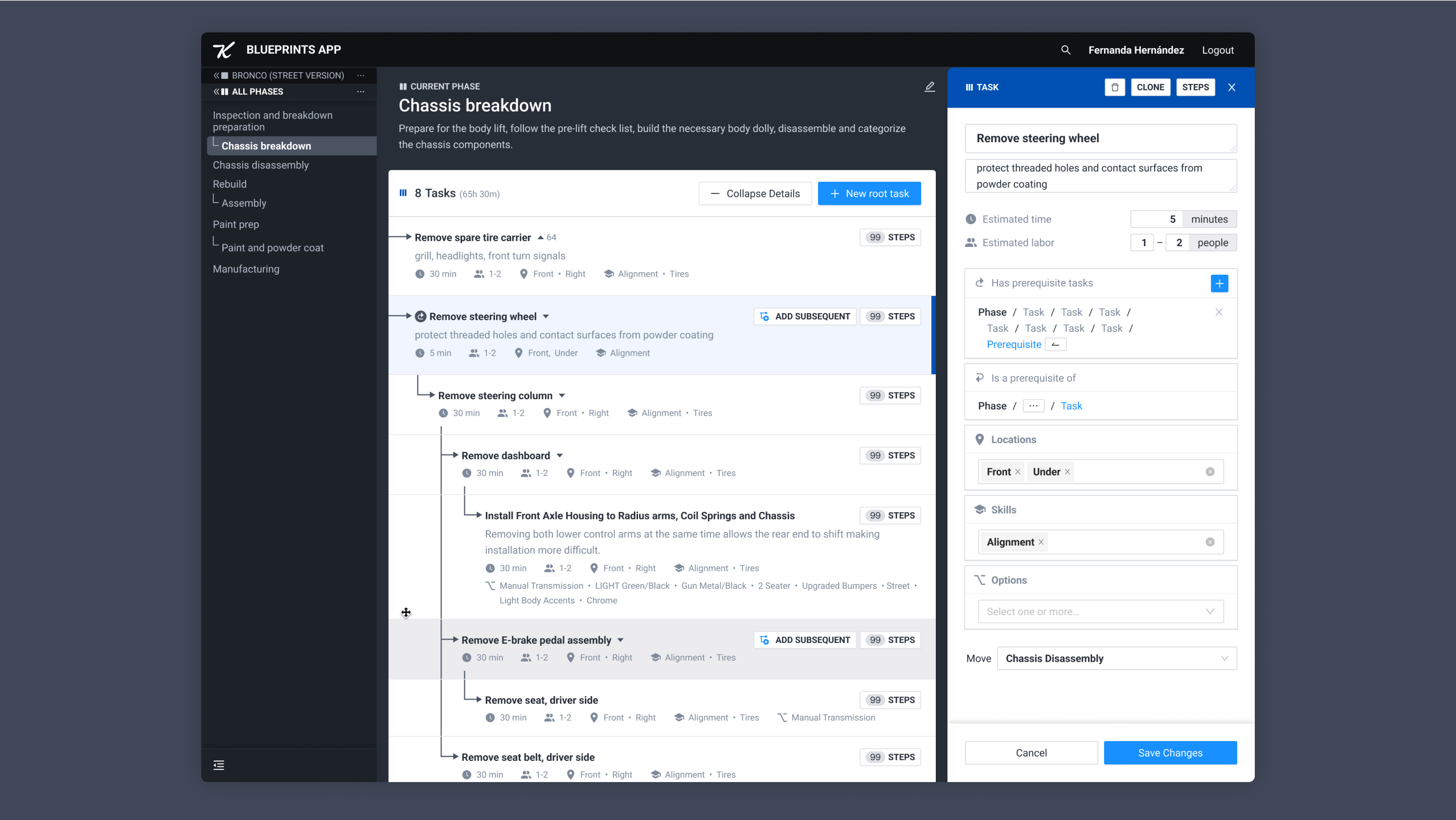

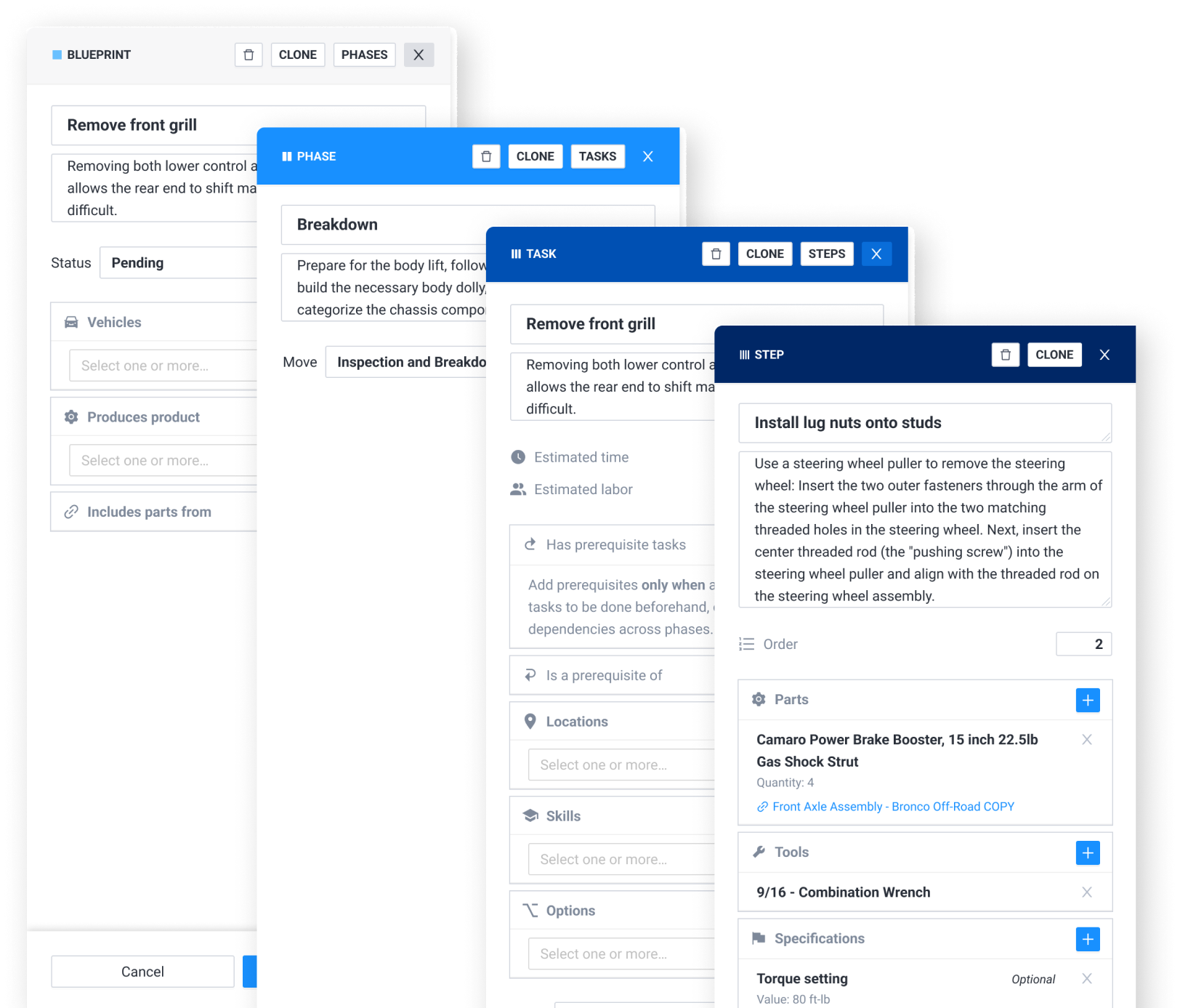

Kindred Motorworks is in the business of modernizing and electrifying classic cars, or in their words, “Making your formerly irrational desire for a vintage car completely justifiable.” Kindred relies on blueprints, the custom teardown and restoration instructions, to allow the team to navigate precise sequences and complex dependencies and ensure safe, efficient vehicle production. Missed opportunities for parallel work would mean time and money left on the factory floor. Incorrect or incomplete instructions could pose a safety hazard.

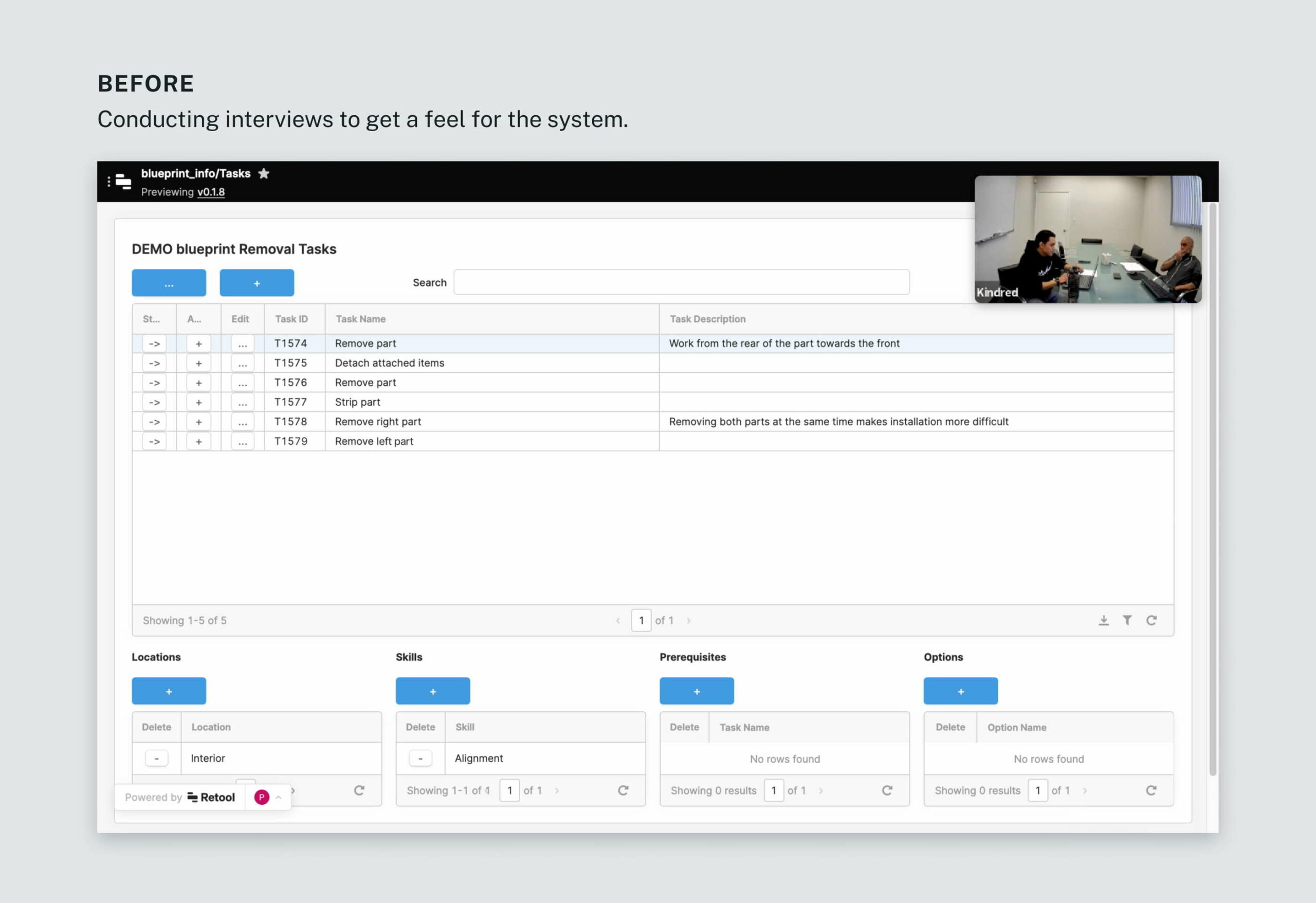

Kindred started with a no-code development tool to validate its initial proof of concept but soon reached the tool’s usability limit. Because this proprietary data was vital to the safety and efficiency of employees, Kindred partnered with Lab Zero to design and build a custom but maintainable application that could grow with the organization’s needs.

Goal

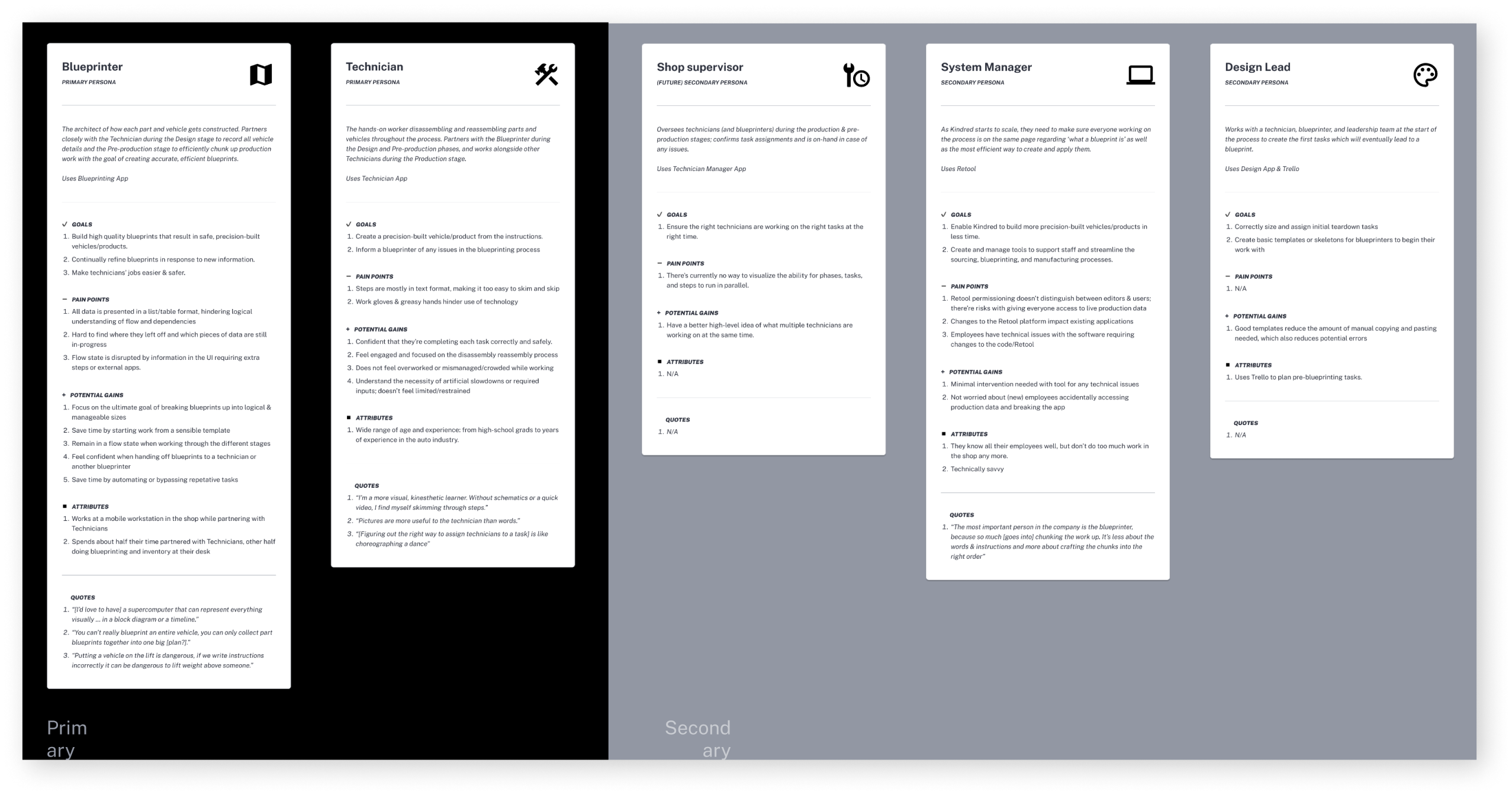

- Understand the needs, goals, and pains of the Blueprinters

- Collaborate with product and engineering to deliver a tool that reduced blueprint creation and validation time

- Mentor a new hire on our discovery practices

Outcomes

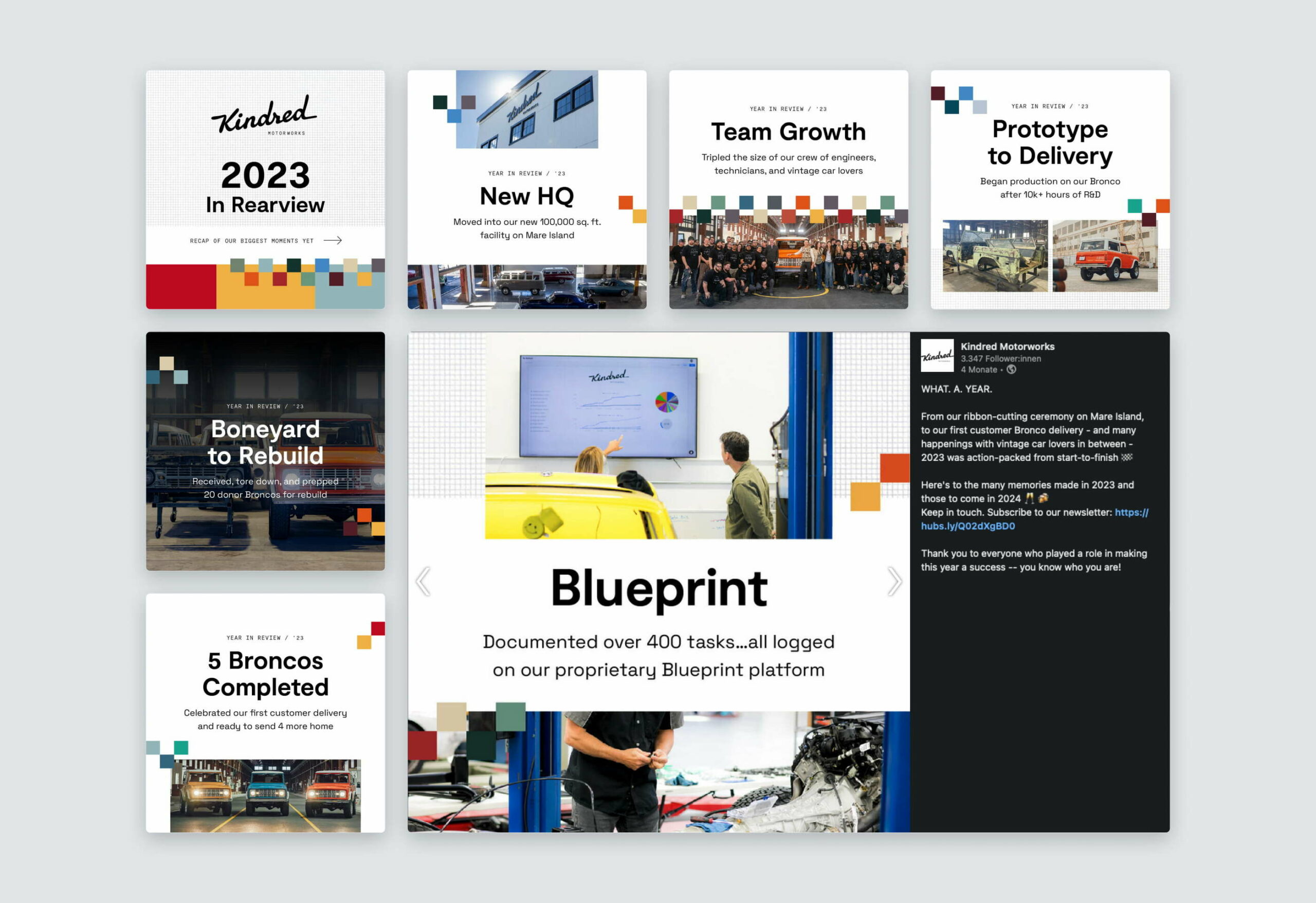

- 400 vehicles blueprinted in the first year: The new tool’s speed improvements allowed the Blueprinting team to create custom instructions for 400 vehicles in its first year of use.

- Enabled client autonomy: We built the tool using the Ant Design System because Kindred did not have full-time design support. Using an established, well-documented design system meant our client would have the tools to continue evolving the application while ensuring usability.

- Increased Blueprinter satisfaction: Blueprinters enthusiastically embraced the tool.

- Enabled new hire autonomy: Our new hire not only mastered out discovery practices but was able to independently take over the day-to-day design activities for the duration of our engagement.

Discovery

Outcomes